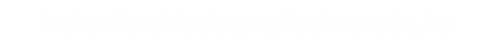

HR-350XC Clay Extruding and Packing Machine

| Name: | HR-350XC Clay Extruding and Packing Machine |

|---|---|

| Model number: | HR-350XC |

| Film width: | ≤350mm |

| Thickness of film: | 40-70um |

| Dimension of film roll: | OUTER DIAMETER Φ ≤ 300mm ,INNER DIAMETER ≤ Φ 75mm |

| Bag size: | (60-145) x (30-165) x (3-55) mm (L x W x H) |

| Speed: | 200 bags/min |

| Power: | 380V,50HZ, 2.75KW |

| Max. extruding diameter: | 30mm |

| Cutting knife type: | rotary cutting, up-and-down cutting |

Product Description

Product Name: 2 In 1 Plasticine, Play Dough, Clay, Dried Clay, Suger Fondant Extruding and Packing Line

Model No.: HR-350XC

Photo:

plasticine packing machine, play dough packing machine, clay packing machine, fondant extruding and packing machine

Scope of application:

This machine is used to extrude and pack light clay, dough clay, plasticine clay, play dough, water based clay etc.

modeling clay packing machine, extruder and packing machine, extruding and packing machine

Technical Specification:

Output |

Up to 150 products per minute |

Size Range |

|

Package cut-off length |

60-200mm |

Product width |

max.165mm |

Product height |

max.60mm |

Packaging Material Reel |

|

Reel diameter |

≤300mm |

Core diameter |

≤75mm |

Packaging material width |

max.350mm |

Weight |

max. 25KG |

Connections |

|

Voltage |

380V,50HZ |

Power usage |

7KW |

Machine weight |

1100kg |

Machine dimensions |

L2350XW1000XH1350mm |

Blade cut type |

Rotary cutter |

Motor configuration |

Dual frequency |

Optional Device |

date printer, gusseted device, water cooling device, heating device, etc. |

air dry clay extruder and packing machine, flour clay extruding and packing machine

Features:

1. The extruding part, dough-cutting part, film drawing part and film sealing part are controlled separately, makes machine run more stable.

2. Man-machine interface, setting parameters by touch screen is convenient.

3. Self-fault diagnosis, the failures are displayed clearly on the screen.

4. High-sensitivity electric-eye tracking and digital input cutting position makes the sealing and cutting more accurate.

5. The cutter reverses when it cut the material, protects the cutter and prolongs the lifetime of packing machine.

6. Independent PID for temperature controlling suitable for various packing films

7. The parts that contact products are made of stainless steel, in line with food QS and medicine GMP health requirements.